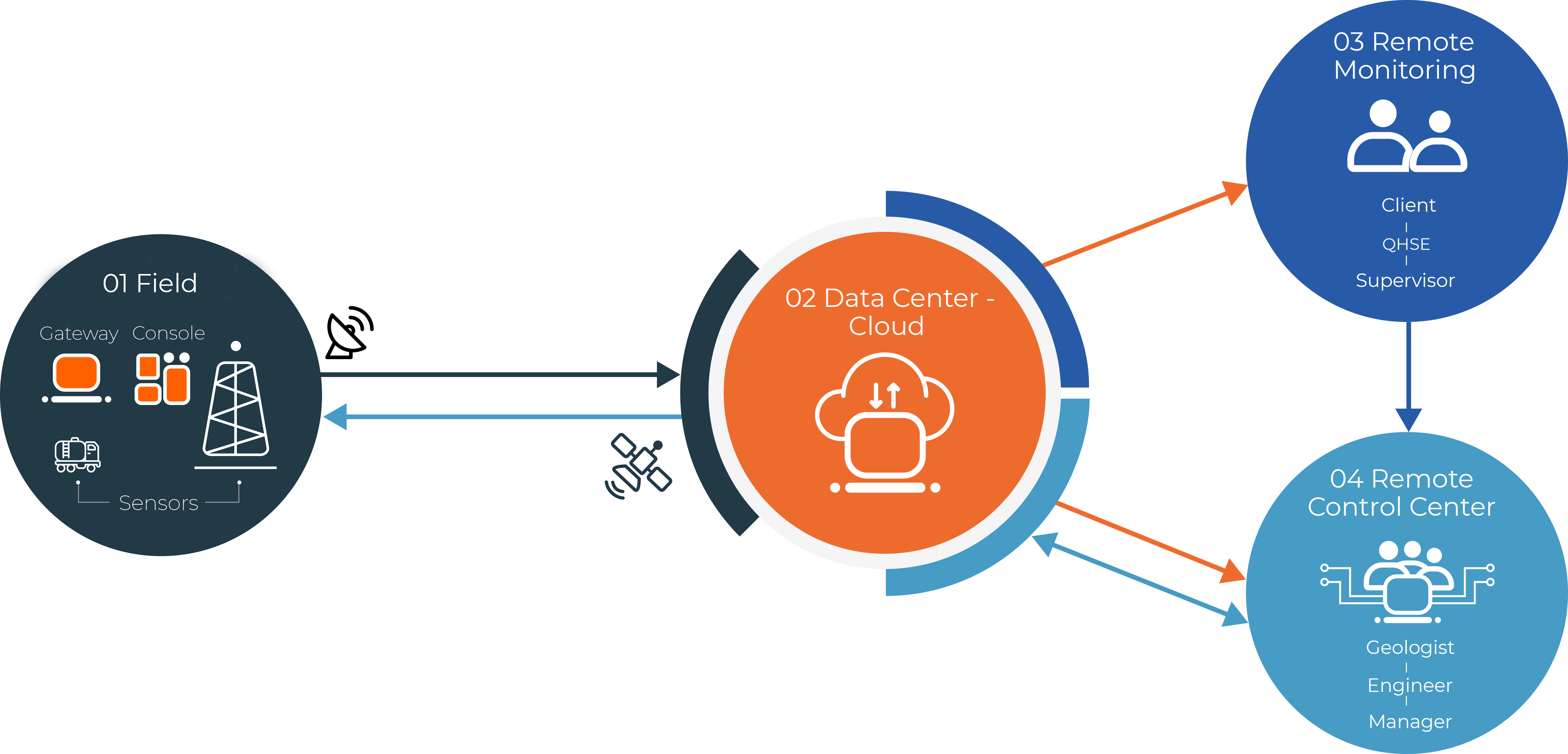

About ECO platform

ECO platform performs a full-fledged analysis of the situation in real time, compares the set parameters and self-calibrates to the actual conditions

Allows all participants of the process to make coordinated accurate, fast and trouble-free decisions

Demo Request

At this stage, the ECO platform allows you to make the calculations necessary for the planning of the profile and casing design of the well, drill string, hydraulics and fluids, as well as used in the selection of a drilling rig and mapping emergency response plan. All planned technological parameters of drilling mode are used, the expected mechanical loads and hydraulics are calculated in the process of drilling, reaming, tripping, running casing strings.

At this stage, input data quality is checked, a self-calibrating "Digital Twin" of the well works, wellbore condition is evaluated, well construction process within "safety corridors" is evaluated, predictive and prescriptive analysis of possible hazards and complications in real time is performed, "smart" alerts with description of corrective steps are set, operations during well construction are automatically determined, automatic reporting is generated.

This block covers retrospective analysis of data on already drilled wells, comparison of data on different wells, determining the performance of different drilling crews, application of best international practices, analysis of causes of non-productive time, accidents and complications, assessment of measures to prevent possible accidents and complications, construction of a roadmap of complications.