Features

Well design

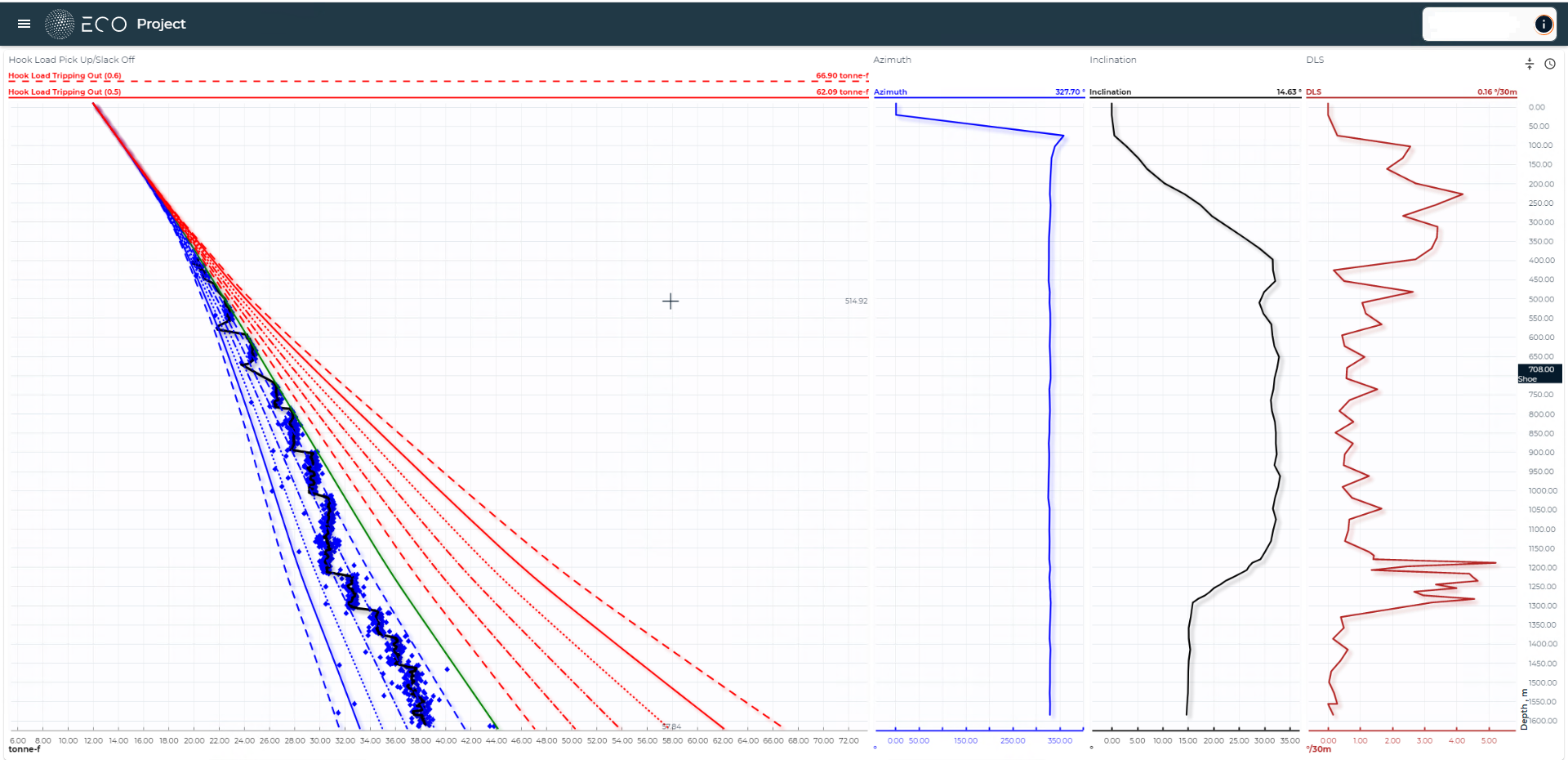

Section Plan

The drilling section plan allows you to estimate the expected mechanical and hydraulic loads in the well for all types of process operations prior to the start of well construction.

Calculations take into account all drillstring parameters, friction coefficients, rheology and density of the drilling fluid.

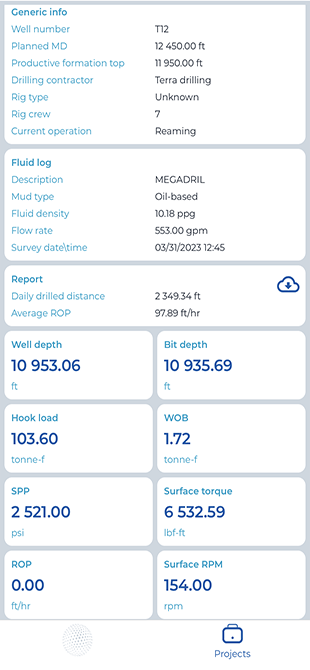

Drilling roadmap

The drilling roadmap serves as a tool for creating and optimizing the drill bit program.

The drilling roadmap contains the planned parameters of technological modes for each technological operation.

The data in the drilling roadmap are filled in according to the "Drilling program", for each planned interval of the open borehole (section).

Well construction

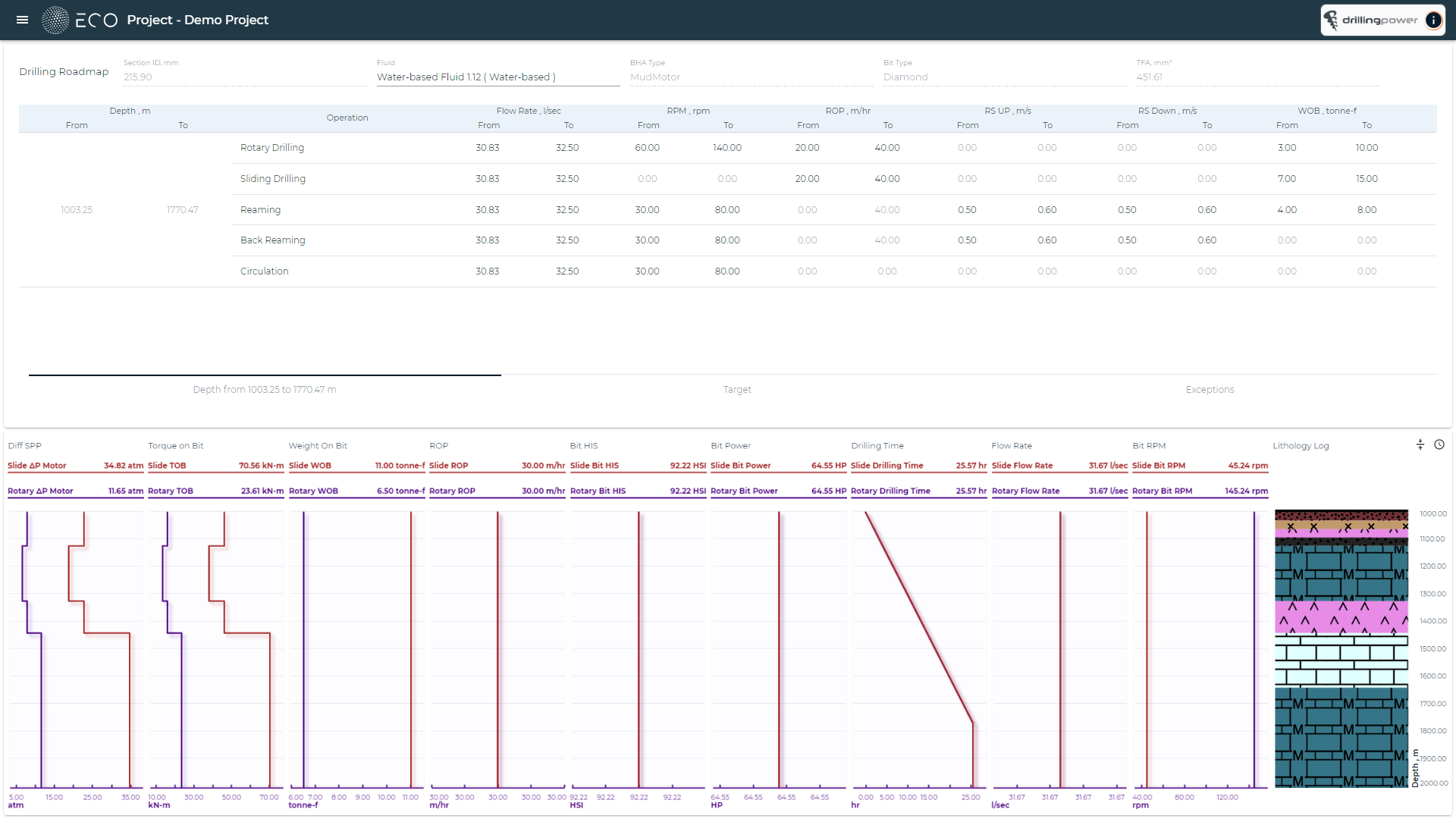

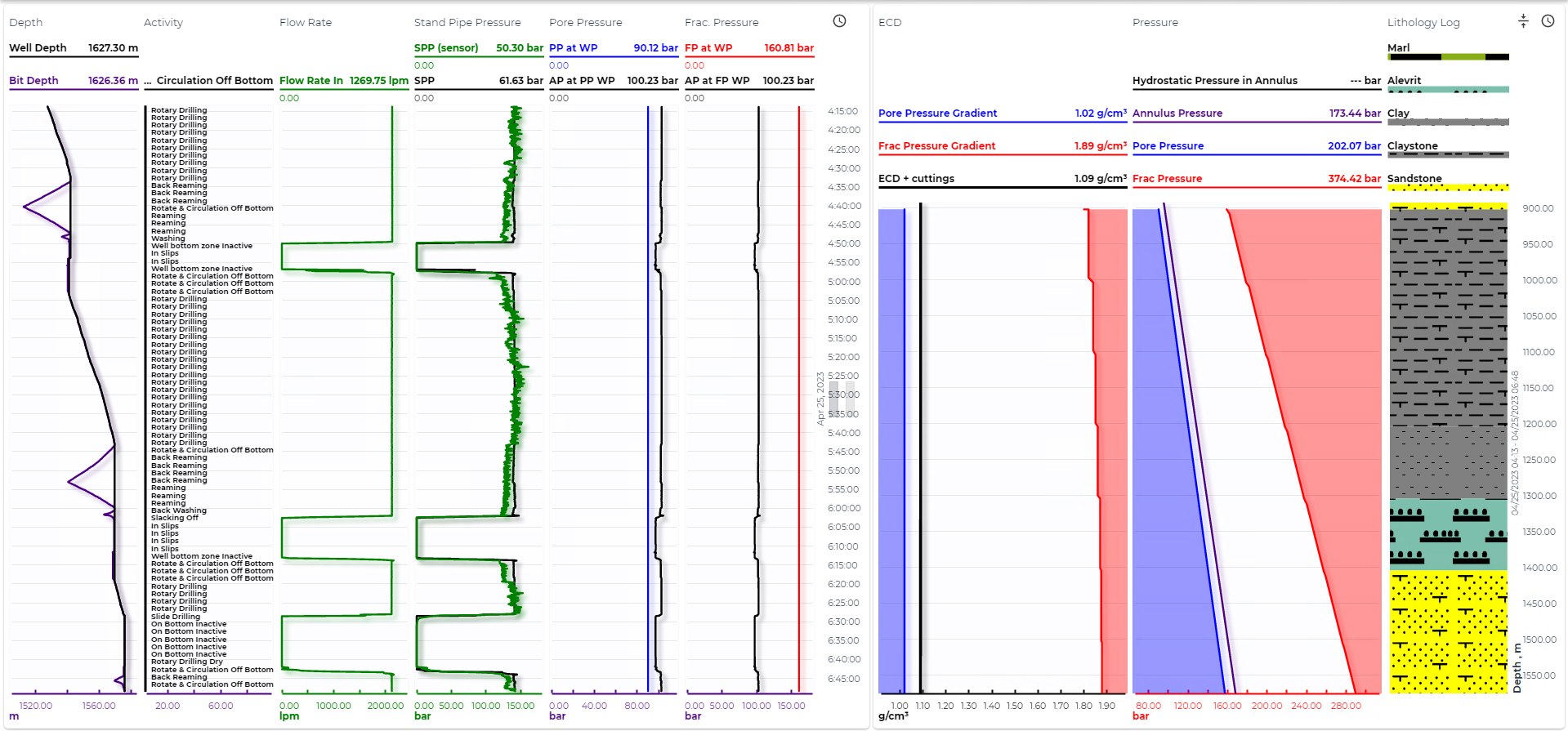

Digital twin

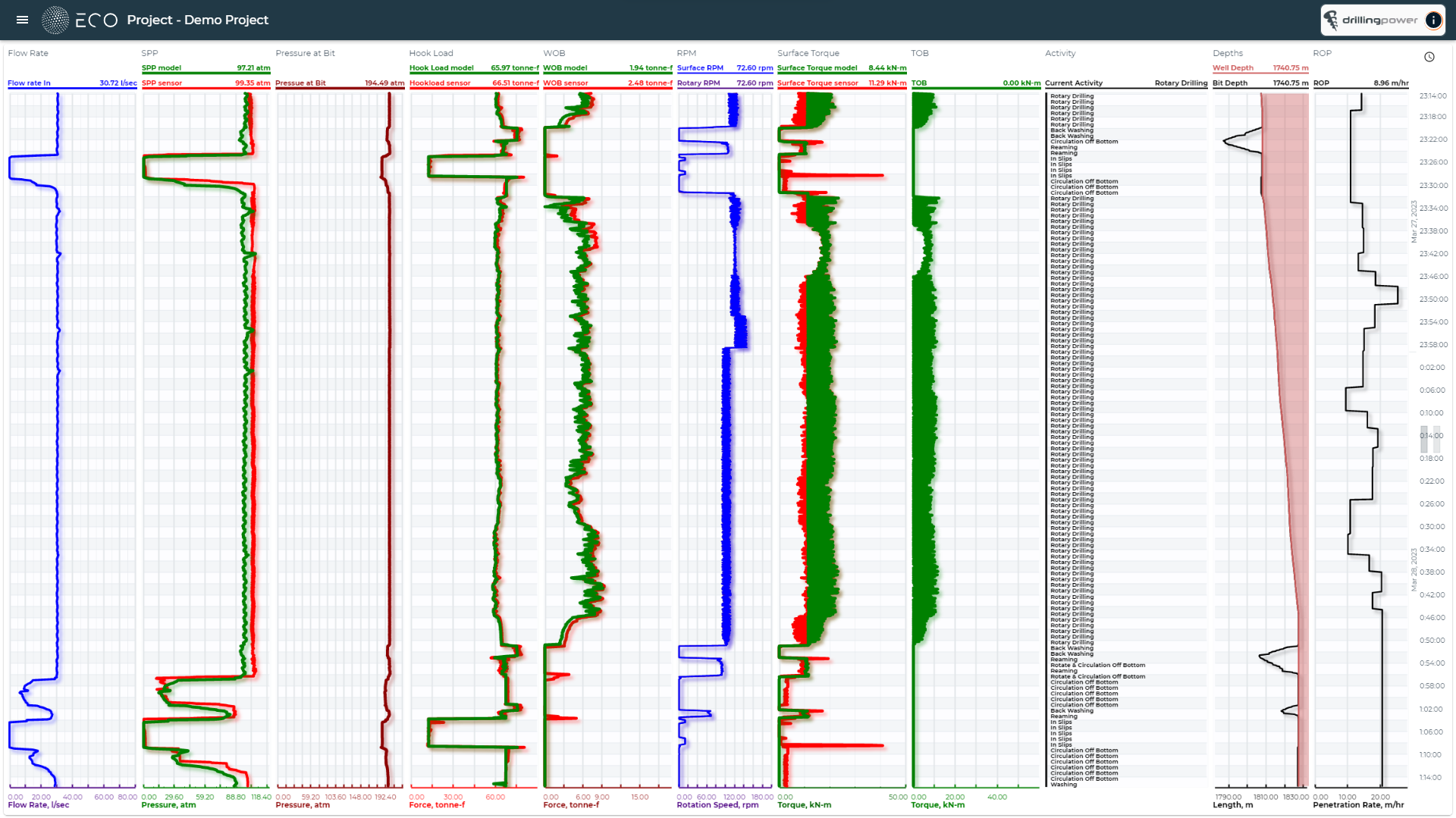

Digital twin is a physical and mathematical model that calculates well mechanics and hydraulics at a rate of 1 Hz.

The live digital twin is calibrated to the current state of the well, based on surface sensor readings (mudlogging, drilling rig, LWD) and automatically determined operations.

Real-time calculations of the digital twin take into account:

- Drillstring parameters

- Mud density, rheology and temperature

- Drilling fluid replacement process and time

- Current well profile measurements

- Current friction factors in the cased and open wellbore

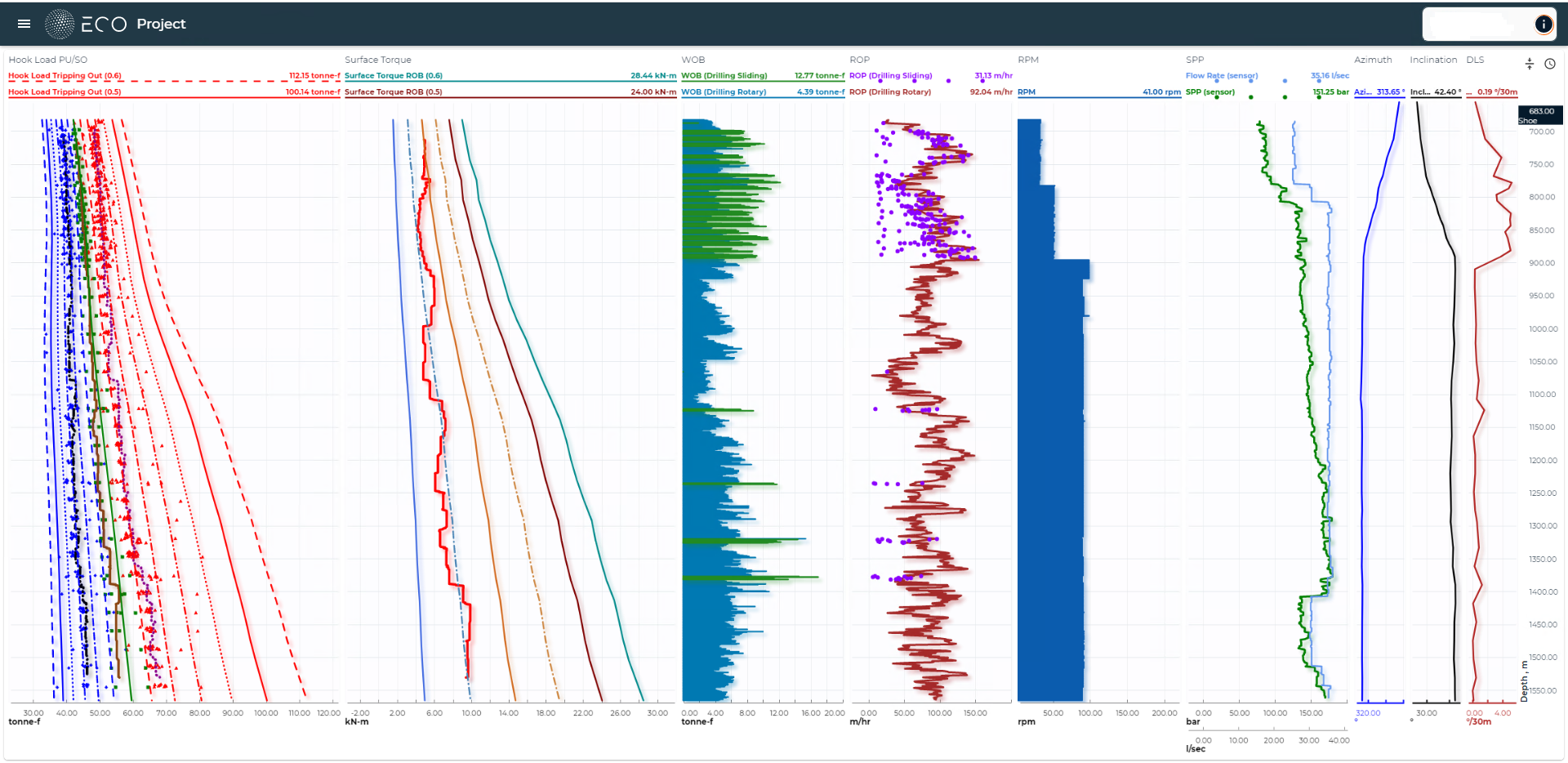

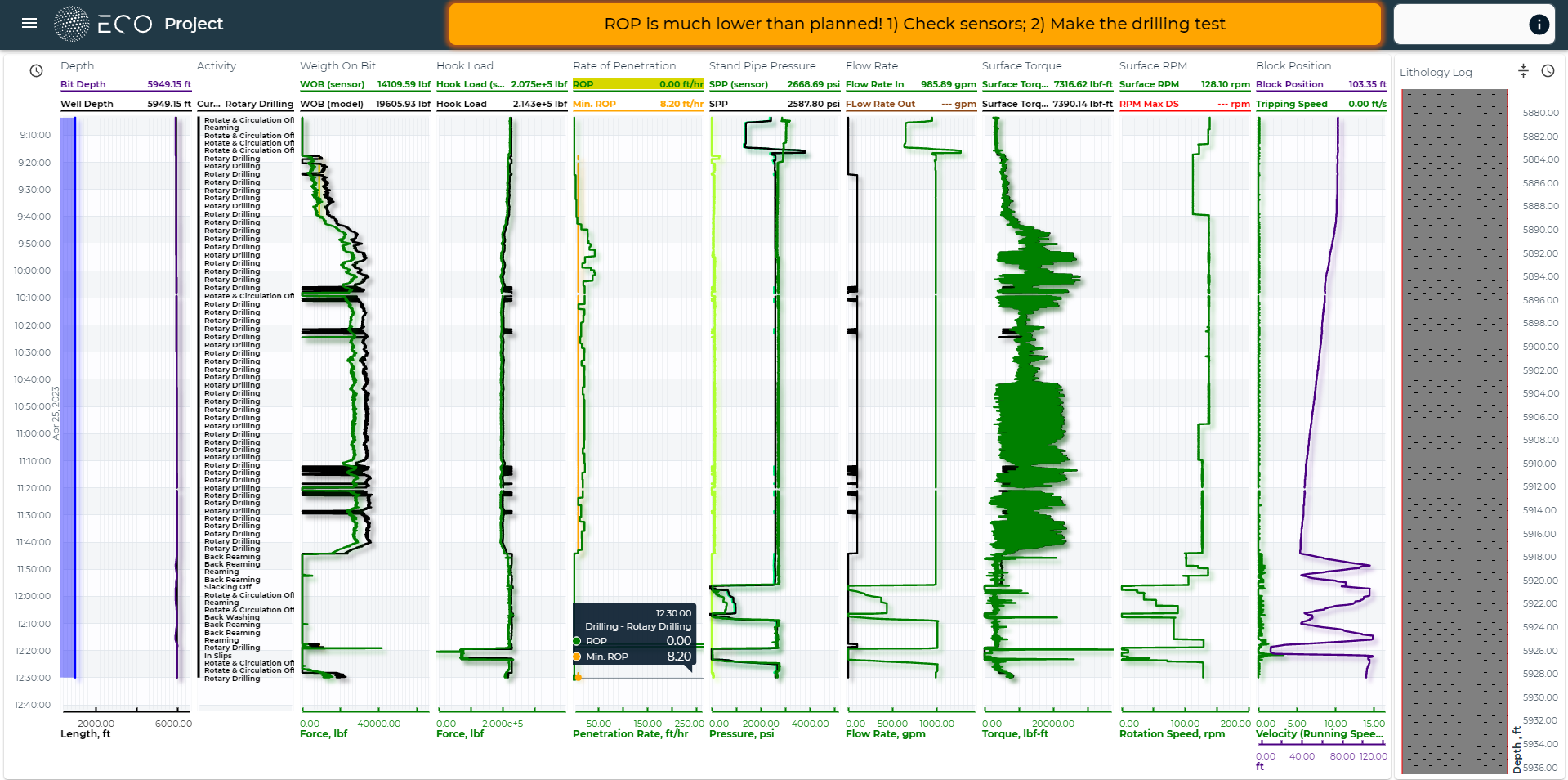

Working in safe corridors

Visualization of the optimal parameters corridor allows the driller to stay within the corridors, thereby increasing drilling efficiency and minimizing risks

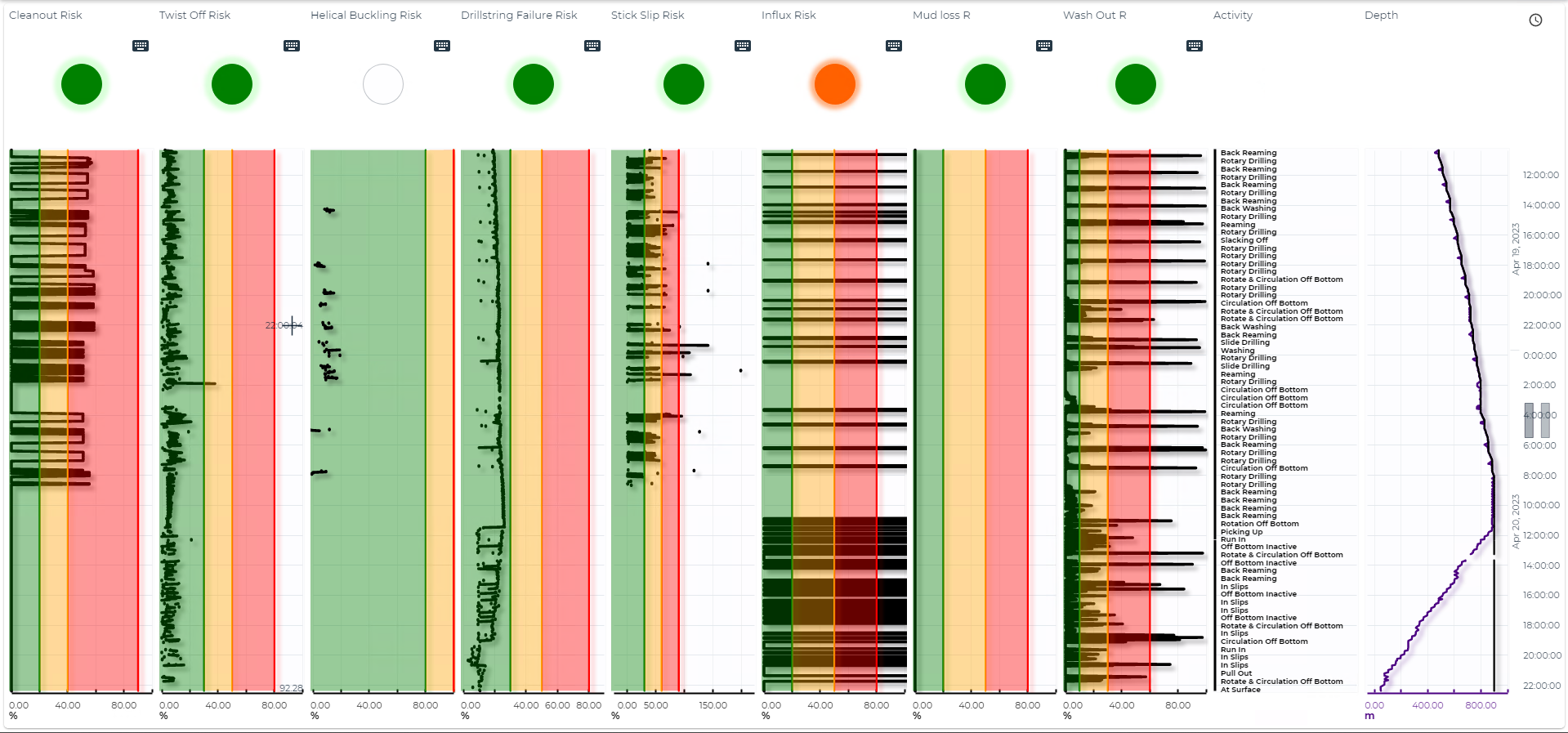

Real-time analysis

Predictive analysis

Predictive trend deviation analysis tools, integrated with hydromechanical analysis and KPI analysis, enable early detection and prediction of pipe sticking mechanisms, potential fluid gains and losses, wellbore cleanup problems, washouts and other problems.

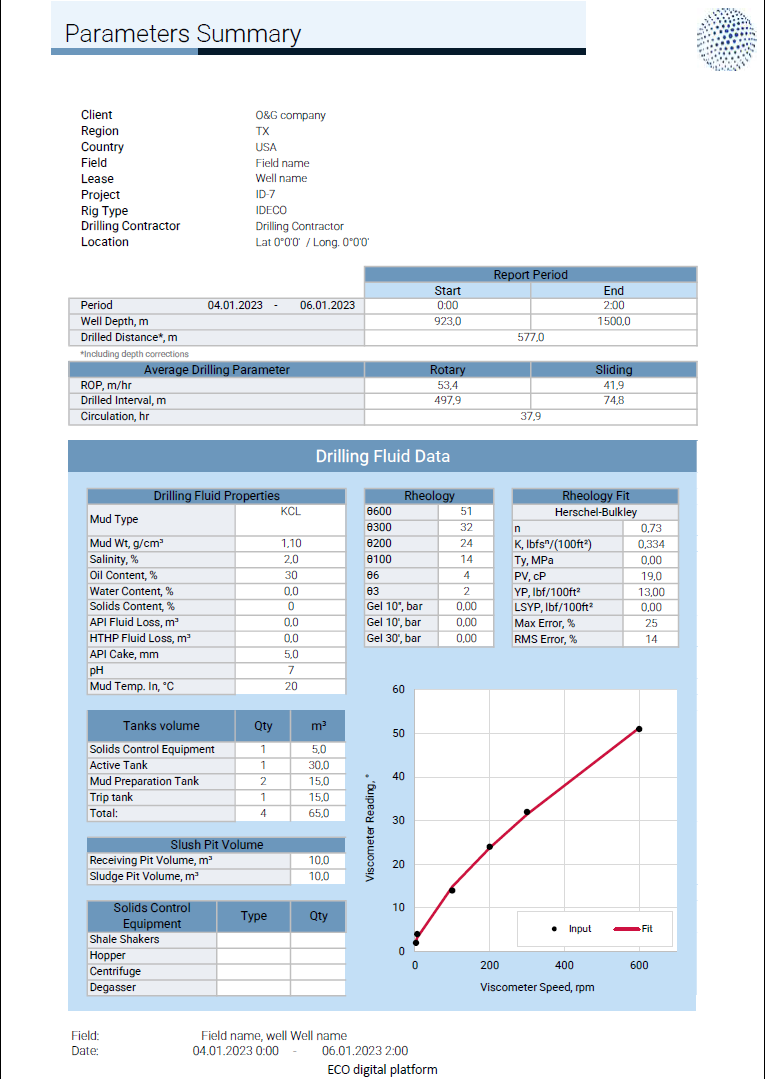

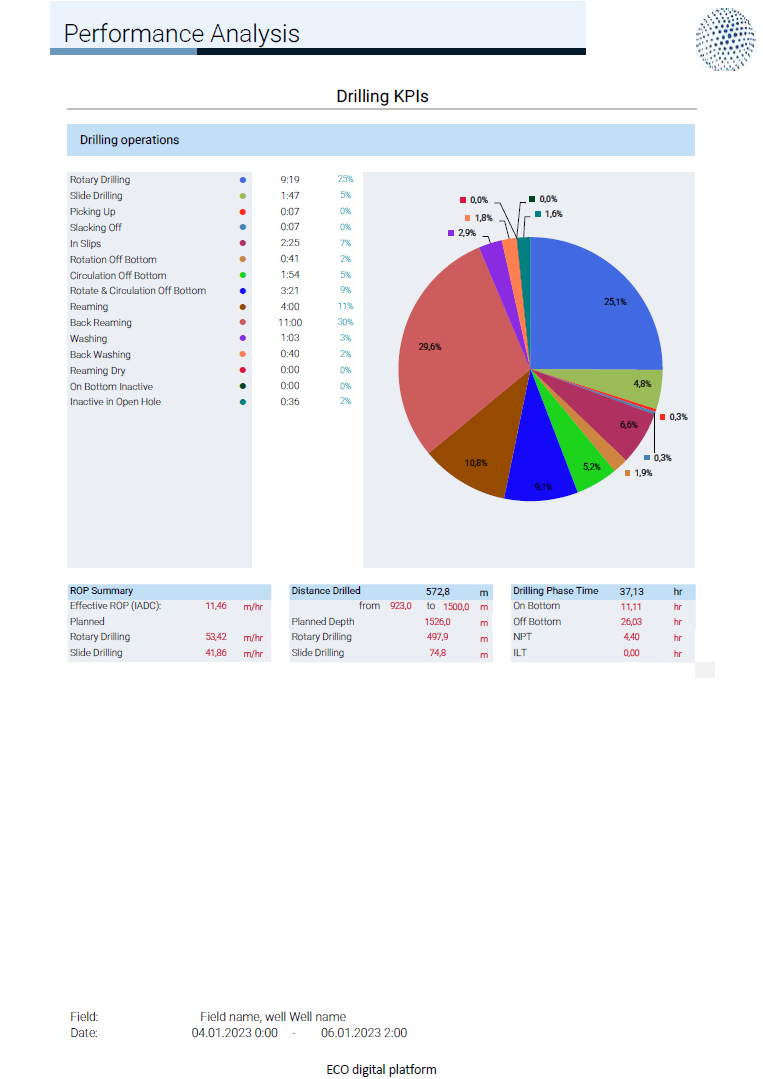

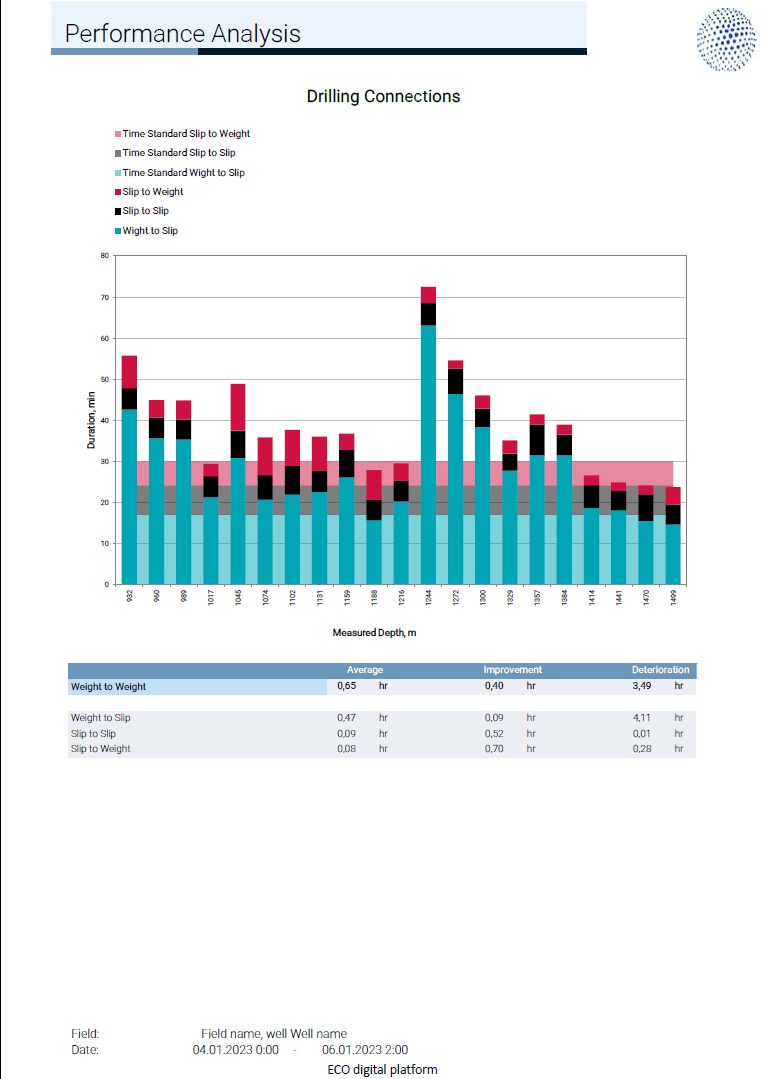

Automatic reporting

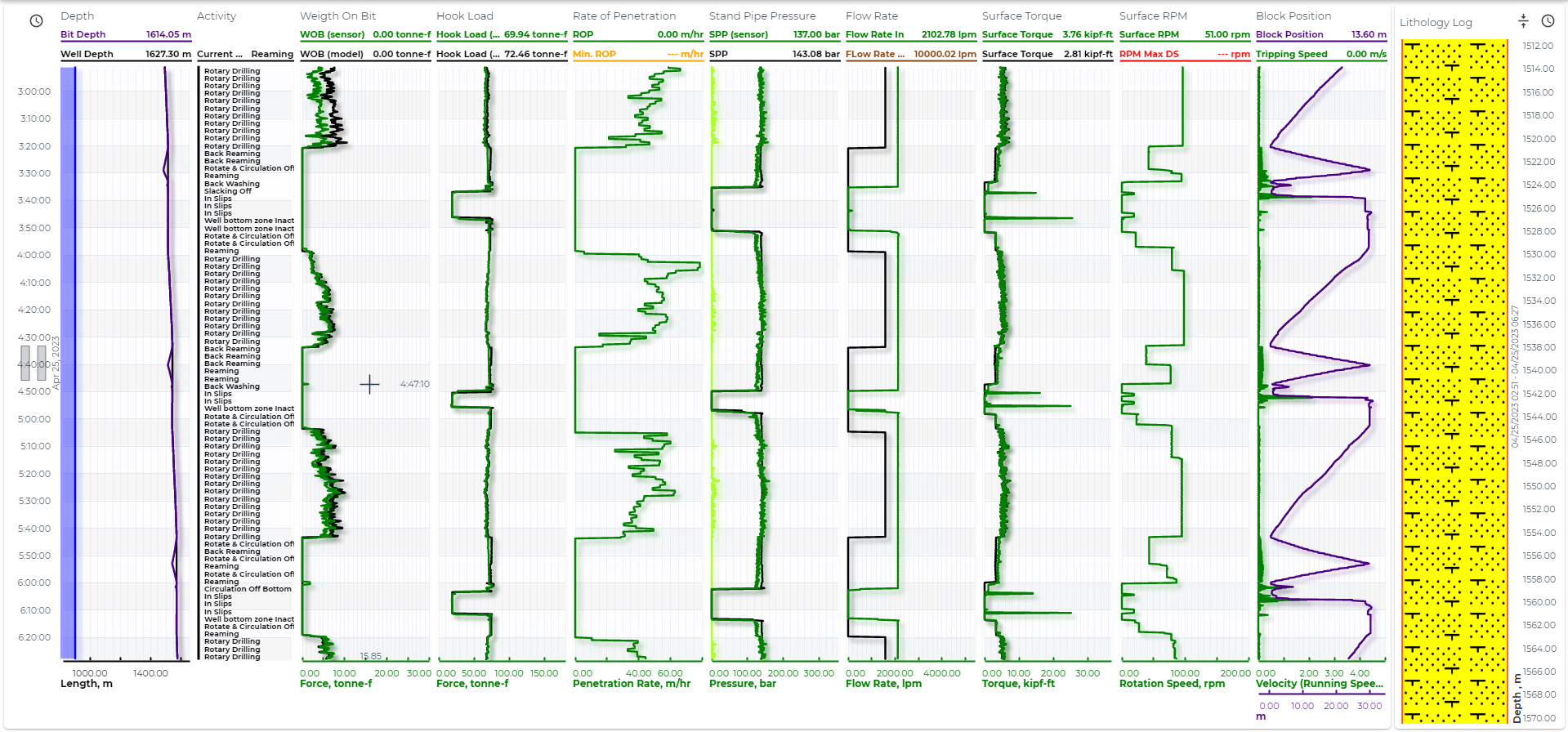

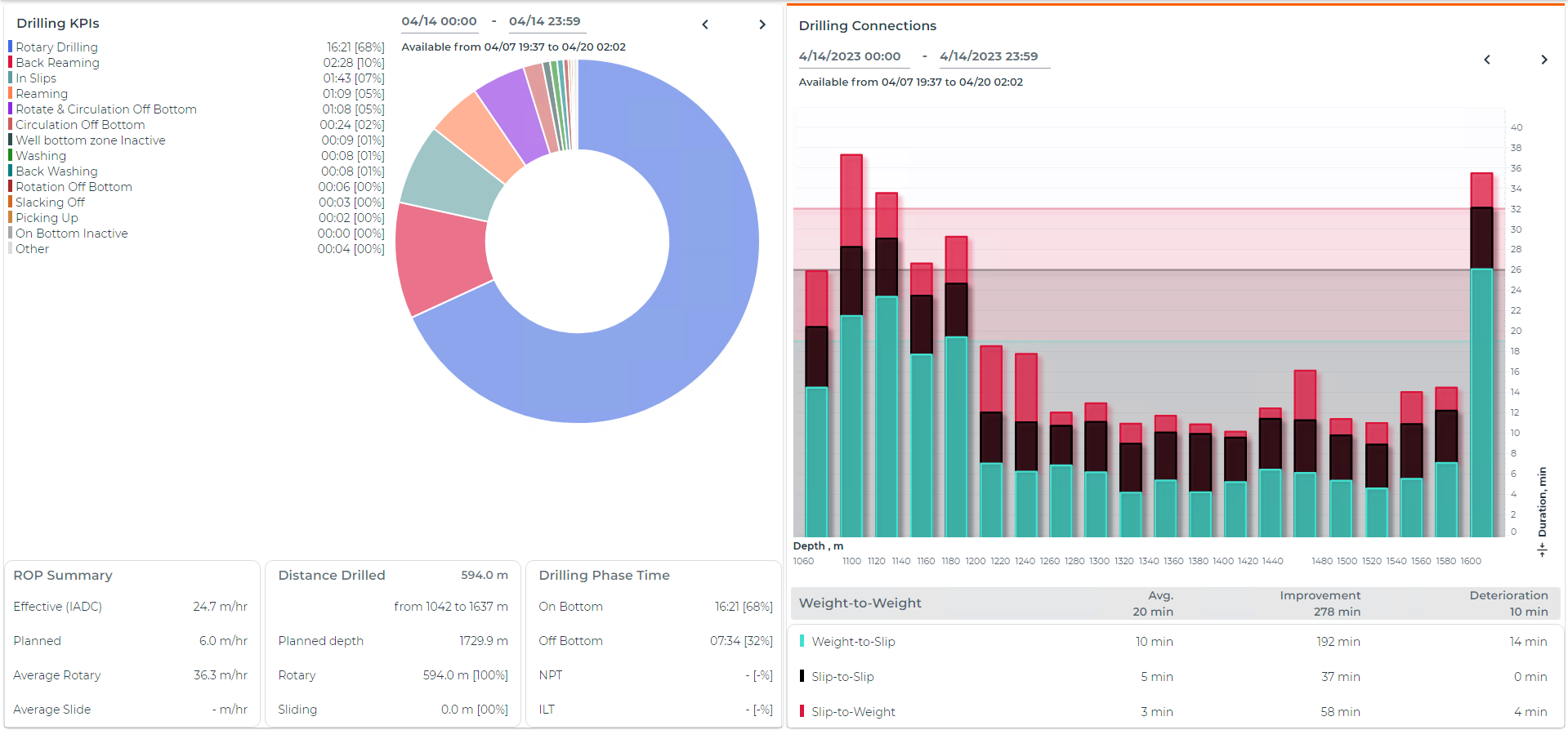

Postanalysis and efficiency

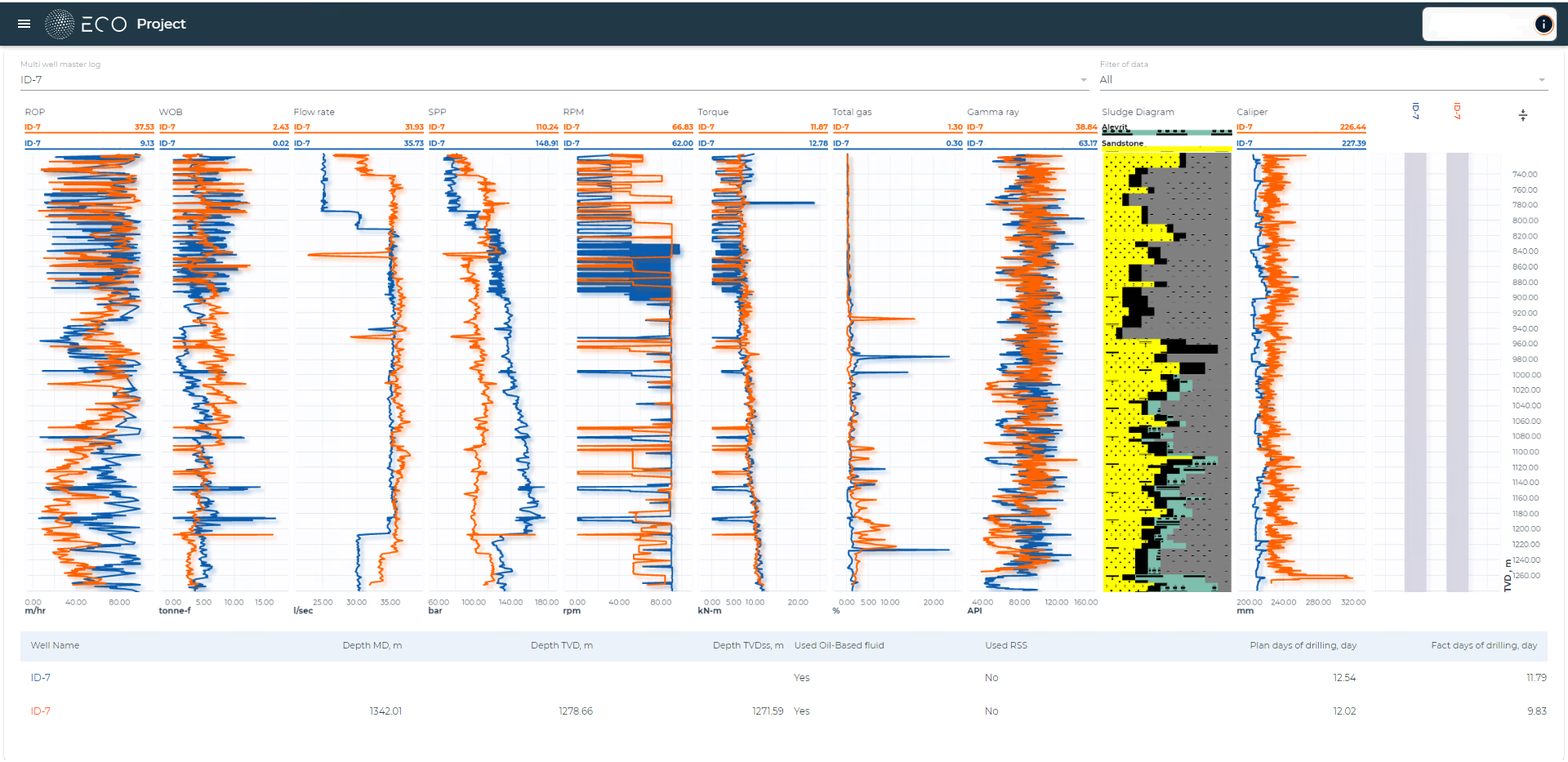

Retrospective analysis

The functionality of the ECO platform allows to run replay of the drilled well data with parallel real-time calculation of all mechanical and hydraulic loads

Processing of historical static data and analysis of well logs allows to clarify lithological information of the reservoir, which will be used in future well design

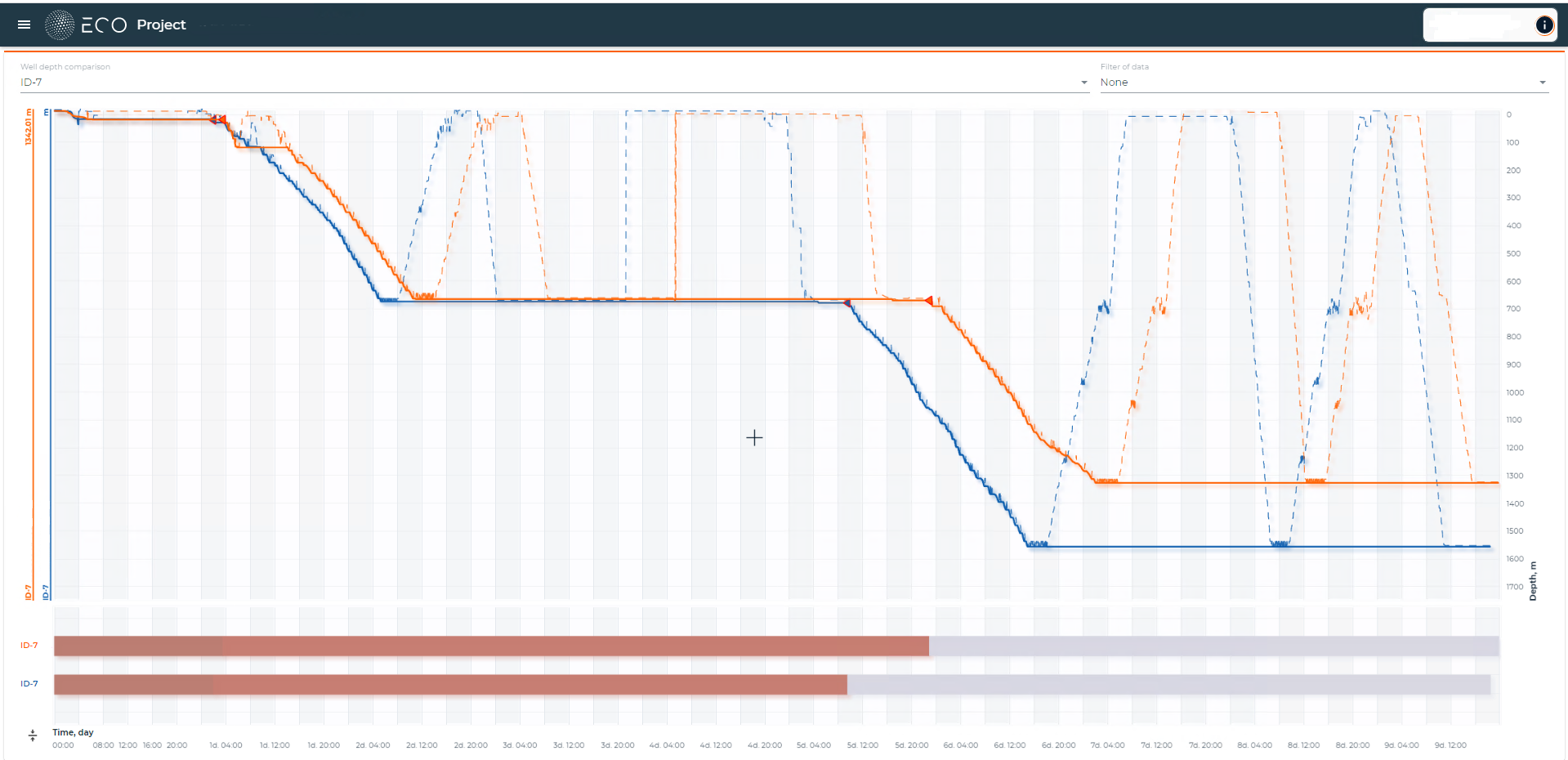

Well comparison

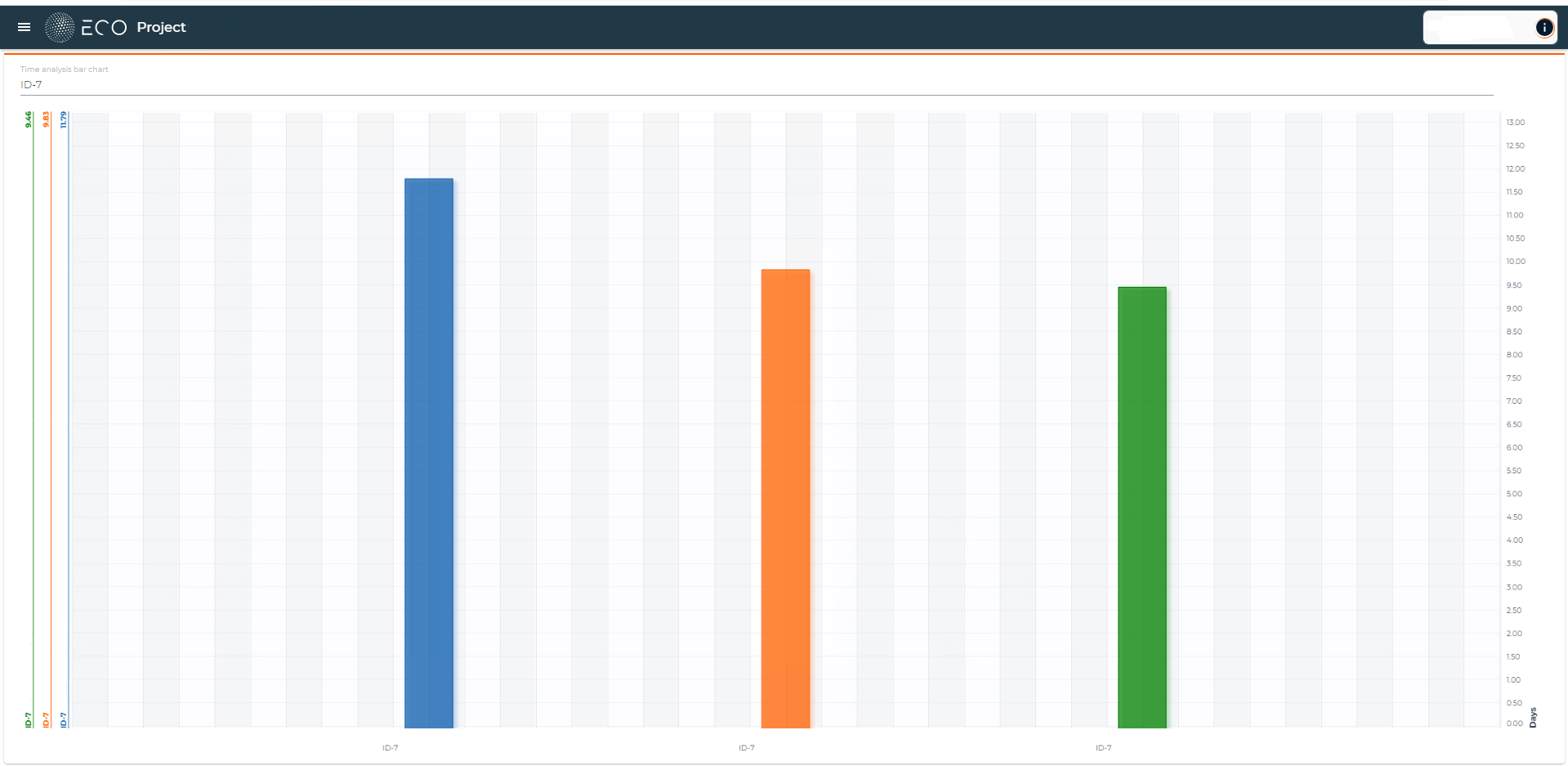

The ECO platform allows comparing different wells for comprehensive analytics and improving the quality of construction of subsequent wells

Simplifies basic tasks of monitoring, tracking and optimizing well construction:

- selection of optimal drilling modes in real time

- selection of optimal BHA design and well construction

- operative control of drilling modes at several simultaneously drilling wells

- determination of efficiency of new technologies application

- optimization of schedule planning

Best Practices

Continuous Improvement Model

Continuous Improvement Model

The ECO platform is a self-learning system that continuously improves the technological process. It allows consolidation and accumulation of all data and competencies within the client company, which leads to reduction of risks associated with subjective factors, growth of personnel competencies and business efficiency