What Is Well Construction Digitalization?

ROGTEC MAGAZINE, January 2022, Dr. Khaydar Valiullin, WellsX LLC

Digital Drilling: Thoughts and Expectations

Today, the entire world is excited by the expectations of the current and future benefits that the digital age will bring to all of us. Phrases such as “digital drilling”, “digitalization”, “machine learning”, “digital twin” became a common air buzz in oil and gas folk chats. Stakes are high and Oil Field Services, O&G equipment and tools manufacturers, Exploration, and Production companies, and investors at no exception are all into it. The race of digitalization has begun for quite a long time ago, to the extent that today we all religiously believe that it “shall direct thy paths” to a better future and prosperity. Petroleum engineers start learning Python, take artificial intelligence-related courses, master the coding skills, while industry in general and E&P companies tend to hire more data rather than geoscientists.

So, what is digitalization for oil and gas well construction? Who are these data scientists, and what do they actually do? The reply and the underlying understanding of the concepts do vary, not only from person to person but rather from the packs of digitalization enthusiasts to a particular corporation. And it is alright, while angles are different indeed, the general understanding does tend to crystalize. Let’s hear some of the key industry experts’ opinions representing the vast digital oil and gas ecosystem. We approached several seasoned experts with a query to define what digitalization is in drilling, and what are the objectives of well construction digitalization.

Pradeepkumar Ashok a Senior Research Scientist from the University of Texas at Austin defines it as:

“Digitalization in drilling involves digitizing (converting to electronic format) all data, information, and knowledge relevant to the well construction process. The goal is to not have data jotted down manually on a piece of paper to be eventually lost. The goal is to be able to store and access all data however specialized they are (top drive specs, bit images, drill pipe usage history, etc.) on demand.”

As for digital well construction:

“The objective of digitalization has many folds: First, is to not lose any data, information, or knowledge gained over the years. Second, to eliminate manual re-entry of data, an extremely error-prone process. And finally, to break down the silos in an organization, to ultimately maximize well construction objectives. “

On the other side of the ocean, Dan Sui the professor of Drilling Digitalization and Automation, Modeling and Simulation, Optimization and Control Systems at the University of Stavanger, adds to it that:

“Digitalization means how to play with data/information with the use of digital tools. Recently data-related digital technologies potentially become a game-changer for the O&G industry. Coupled with the sensors, high-speed data transfer, and data management, and digital simulators, the intelligent and automated drilling systems to make the best decisions, provide good recommendations, and detect early faults become closer to reality. In short, drilling digitalization covers and needs data-related technologies including sensors technology, software engineering, data science, mathematical modeling, AI, control systems besides petroleum engineering to reduce costs, increase efficiency and keep safe from planning to operation and post-analysis.”

According to Ms. Sui, well construction digitalization is about:

“How to make an optimal well plan with the use of digital and automated well design tools (trajectory design, mud selection, pipe/BHA/casing design, and so on). How to get meaningful, high-quality data for information interpretation. How to develop digital twins to help drillers make good decisions. How to integrate data for post-analysis. The related research topics/objectives can be: how to model drilling dynamics precisely and accurately; how to integrate drilling models into one simulator which considers drilling hydraulics, drilling mechanics, and their interactions; how to use deep learning technologies to create a self-learning environment to train and calibrate models based on data; how to develop a smart and robust simulator to easily adapt to different wells and different drilling environments; how to provide right, useful and prompt to guide users’ decision and optimize drilling operations.”

Alejandro Lammertyn, Chief Digital and Information Officer of Tenaris – one of the leading well construction products suppliers define digitalization in drilling meaning as:

“Bringing data, on a real-time basis, to the place or moment when decisions need to be taken. Helps coordinate activities from different players, particularly service companies and product suppliers that normally interact in drilling activity. Understanding data that is coming from the field is essential for directional drilling and increasing the probability of success”.

How about the prize?:

“In the case of well construction, on top of data availability, what is more, important is planning and structural checks real-time. On planning, we see the opportunity of coordinating all supplies at the same time, minimizing inventories, and reducing waste. On the structural check side, we see a huge opportunity in analyzing torque and depth and stress and fatigue forces on the pipe and connections. It is essential to arrive to the final depth and optimize the productivity and cost of the well.”

Crispin Chatar Drilling Subject Matter Expert with Schlumberger, undoubtedly one of the major OFS companies that are pushing the industry technology development to its boundaries, thinks that:

”Generally, digitization refers to leveraging digital technologies to add value to digitized data. In drilling or maybe more accurately in well construction, I think that digitization refers to utilizing a framework of digital technologies that can be aligned with the current goals of the industry. Take for example emerging technologies like vision analytics or voice interfaces which in recent times have been bringing value not only to other industries but even in our personal life. We can take the existing data frameworks, create some new ones, and then use our digital data to feed systems that will bring value through insight. Consider moving from delivering a paper log to delivering the data in a completely different way. There may be different tiers of digitization as well. That log could be delivered on a memory stick and that would be digitization, or it could be uploaded to a cloud or even used for a digital service in real-time. Our digitization could focus on some of the main areas such as Machine learning, Cloud technologies, Extended Reality, User Experience, big data, Internet of Things and High-performance computing just to name a few examples.”

How do you see the objective?

“The goals of digitalization for well construction should be to increase safety and improve efficiency. We can then break that down further but at the highest level, that’s what it’s all about.”

On the other hand, Adebowale Solarin, Director and Head of Drilling & Wells Operations Support at Maersk Drilling opinion is that:

“Digitalization in drilling refers to process standardization, information collection, and information visualization. Utilization of such information in the right context enables automated, data-based execution of various operations. Ideally, digitalization also enables us to implement operational lessons learned and utilize previous positive experiences. Digitalization helps to improve efficiency, safety, and decision-making because a wider range of factors can be taken into account based on data.”

As for the objective:

“To me, the objective of digitalization is to help the industry become smarter in all areas of the business by utilizing the large amount and range of gathered information and data to make informed decisions. It enhances collaboration and supports our journey to become a safer, more efficient, more profitable, and more responsible Drilling Contractor.”

While Alexander Ryabchikov Projects Head at GPB-Engineering identifies drilling digitalization as:

”The ability to collect all drilling data in real-time. Analyze it using pre-established operational safe envelopes, which were calculated based on the specifics of well design and drilling programs. Hence, it is an enabler to control and manage a well construction process at all stages of its operational decision-making process.”

What are the objectives of digitalization in the well construction process?

“For the customer – the availability of processed and analyzed information about all processes makes it possible to have clear control of the contractors’ performance and quality. And the presence of a database allows you to make informed decisions when accepting the work performed. After completing any of the well construction stages, make changes to the well design and drilling program quickly and easily.”

According to Wikipedia:

“Digitization is the process of converting information into a digital format. The result is the representation of an object, image, sound, document, or signal by generating a series of numbers that describe a discrete set of points or samples”. Astonishingly simple, precise, and same time quite a vague definition while applied to the oil and gas reality. My peer’s opinions are the bright reflections, of those different angles mentioned earlier above. It does contain some slight “diffraction” caused by their professional activities, which do add a variety of colors to the picture of objectives and opinions of what is digitalization about in O&G. The latter though does not change the main theme of this colorful picture. There is a lot in common between various beliefs. In the opinion of the author, the common ground is that the process of digitalization is multidimensional, multidisciplinary, and does involve a conglomerate of technologies, that are evolving at their own pace so far. We see that, despite the difference in approaches to setting the problem, to the methods and tools for solving, all respondents from different countries are unanimous in one thing: we all expect only a positive effect from the introduction of digital products into our daily life.

Back in 2017 according to Deloitte analysis reported in the “From bytes to barrels” white paper, the Oil and Gas industry was still about “teenager” maturity levels, a hair below where it is supposed to be. Same time according to the Deloitte analysis well construction explorational and development, drilling advances prevailed the production ones.

*Source: Deloitte analysis: deloitte.com/insights

From the Report by the Deloitte Center for Energy Solutions:

“From bytes to barrels. The digital transformation in upstream oil and gas”.

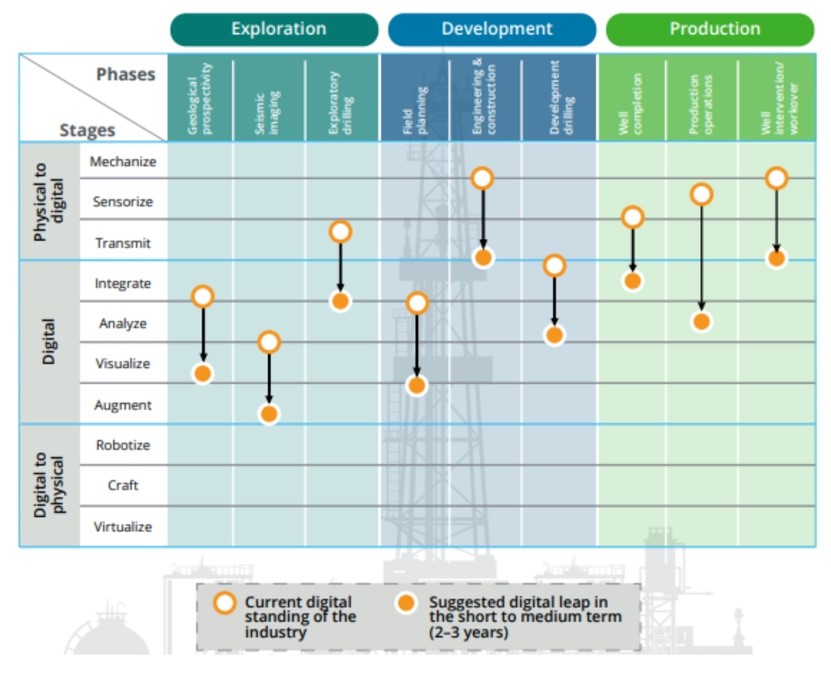

Figure 1. Digital maturity and near-term digital goal mapping for upstream operations: a view back in 2017.

Almost four years passed, and the question is: did we as an industry achieve the desired state? has the digital leap taken place? Are we approaching the desired objectives, the prize, and if not so, why? Let’s check what my peer’s dealing with it on an everyday basis feel about the challenges we all face along with the digitalization transformation.

In the opinion of Professor Sui, the main digitalization challenges are:

“Need dedicated engineers with multi-disciplinary knowledge adapting to the newly developed technologies. Need smart sensors and good data processing technologies. Encourage data sharing and benchmarking. Encourage code open sourcing. Need more field tests for smart digital twins”.

Mr. Lammertyn one of the chief officers of the leading supplier of steel pipes and related services for the world’s energy industry sees:

“The challenge in Digitalization in this market is to create long-term relationships between customers and suppliers that provide the ecosystem to innovate and create value together. As long as relationships are transactional and depend on optimizing the bottom line on a spot basis it is very difficult to create value and advance in a Digital Transformation.”

Mr. Chatar or “the drilling guy” of international industry-leading technology innovator OFS company says:

“Today, for me, the number one challenge is the rate of adoption. Historically, our drilling has been split into high tech and high volume with one side adopting technology faster than the other. Digitization offers the promise to bring value to both if we can adopt early and be agile in how we create and deliver solutions. This goes for service companies, operators, and drilling contractors alike. There are other challenges such as sourcing the right technology and then applying those technologies to the right use cases. Another challenge is trust between the companies in our industry. Other industries have found that openly sharing data is the best way to accelerate progress. Data of course has a cost and contains in most cases proprietary information about business and the world”

Mr. Ashok senior researcher at one of the leading US academic institutions and an entrepreneur thinks that:

“One of the main challenges to digitalization is existing workflows associated with the execution of the well construction process, and the lack of incentive to invest upfront in this change. Another challenge is the lack of standardization when it comes to data storage – though this problem is beginning to be tackled by OSDU”

Alexander Ryabchikov engineering firm head of department sees it as:

“The main problem is to convince potential users of the need to move to the digitalization of drilling processes.”

Mr. Solarin director of a leading offshore drilling operator, notes that:

“The industry is known for being notoriously conservative when it comes to embracing new technology, but this is changing. The recent downturn has forced us to think smarter and the best tool for this smarter thinking is digitalization. Another challenge is the large amount of investment needed for the implementation of digitalization initiatives. The companies that have successfully come out on the other side of the downturn must be prudent and cautious with spending. A strong and fool-proof cost-benefit analysis is essential for a digitalization project to get the green light.”

Digitalization: a journey with pit stops or a never-ending marathon

Regardless of its definition digitalization is inevitably associated with the following components: software, firmware, and hardware. The latter two are rather not new for the industry, but how about software? Is smart software being the final purpose of digitalization? Will this software be the enabler of automation, will it provide systematic and actionable insights based on structured and quality data?

According to many, automation is one of the pinnacles of digital transformation in drilling. Industry joint efforts in this direction have been taking place for many years and in different forms and scales. Back in 2008 SPE volunteers formed the Drilling Systems Automation Technical Section DSAT. One of the efforts of the DSAT section has focused on outlining a technical roadmap for drilling systems automation and is divided into several technical challenge areas. Further on IADC Drilling Engineering Committee approved JIP focused its effort to describe a vision for DSA and the steps that may be taken to move the industry forward and to affordably achieve this vision.

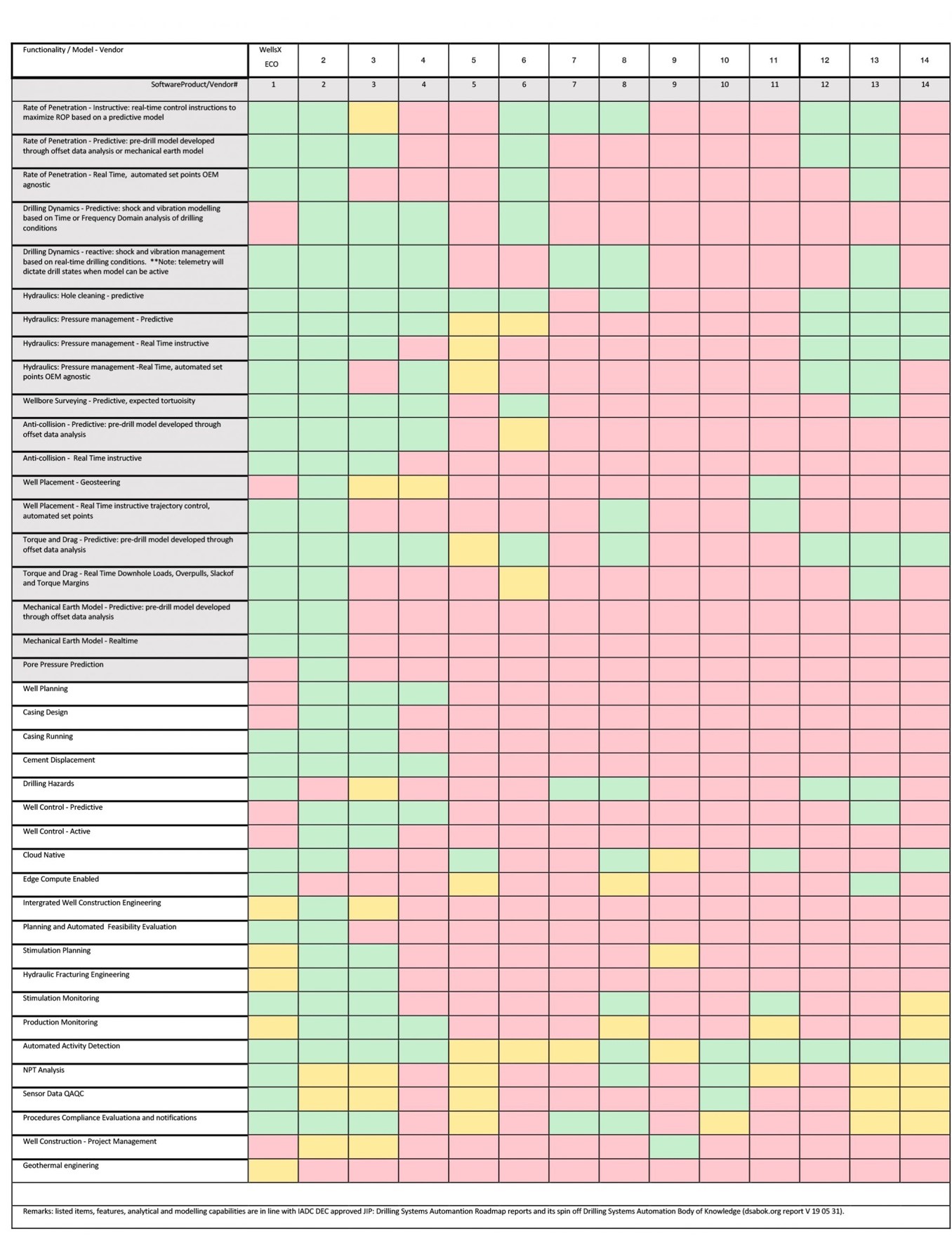

These identified steps practically are the software requirements. Indeed, they are not covering all discussed above aspects, though still do cover almost half of it to our opinion. For the sake of identifying the current state of the industry, we have combined the DSABOK latest reported list of critical features and functionalities required to enable automation with the expert’s opinions and internal WellsX vision. The resultant list has been compared with the key commercially available industry software solution providers declared features, deliverables, and underlying software technologies (see Figure 2.). The obtained picture needs to be underlined to our best knowledge and is quite colorful. It might not be the most precise one can say.

Figure 2. Landscape of well construction key software solution as per summer 2021

At WellsX, we believe that digitalization and software have long become an independent fourth part of the classic People – Processes -Technology formula, and not an auxiliary function to the first three. Based on our vast technical, software development, manufacturing, and operational experience, in virtually every oil and gas province in the world, we have spent the last five years developing an industry-leading product called the ECO system. To date, the digital platform has been successfully deployed in seven countries on four continents, and this number is actively growing to the satisfaction of our customers.

We developed ECO to be agile, open to the Client, flexible to rapidly comply with our customer’s particulate local needs and objectives. The concepts of data quality and integrity assurance and control, holistic multidimensional process transparency, automation of all routine processes, reporting, visualization, and notifications, up to direct equipment control are embedded into the overarching paradigm of system architecture. We see digitalization as a marathon rather than a journey with an end. Digitalization in O&G is not having its final destination in our vision. Nowadays reality states that software is a key and necessary evergreen creature of the energy industry ecosystem. Software technologies evolve with a pace of speed of sound, these simple fact makes any digital technology outdated and useless in a short time once its development is on hold.

ECO system: Digital platform and client.

Digital ECO system is a software, platform entitled to serve the needs of all parties being involved in upstream, starting with well feasibility studies, inception engineering till the very end of its lifecycle: conservation or abandonment. At a current state of ECO evolution, its primary focus is Well Construction – Production interval lifecycle scale with a meticulous zoom on the engineering-related specifics of geomechanics, well hydraulics, and mechanics. The live digital twin model of the well and downhole tools within ECO serves as the prospect wells engineering core engine as well as retrospective and dynamic real-time analytics train. The analysis is performed coupling all physics-based models with data insights via statistical and regression analysis allowing the Client to achieve vital insights in a real-time pace of 1 Hz, have an exceptions timely manner response preventing drilling hazards and downhole complications well in advance they are passing the no return point.

Ground zero platform functionality allows ensuring data integrity, assure data quality, secure data access, and holistic project information aggregation- knowledge repository. A step above, its digital infrastructure structured hierarchy performs project, associated equipment, personnel, and vendors management and allows to effectively communicate. All project parties talk on the same numbers, receive common or dedicated notifications, prescriptive analytics insights, and do utilize a common intuitive and dynamic interface.

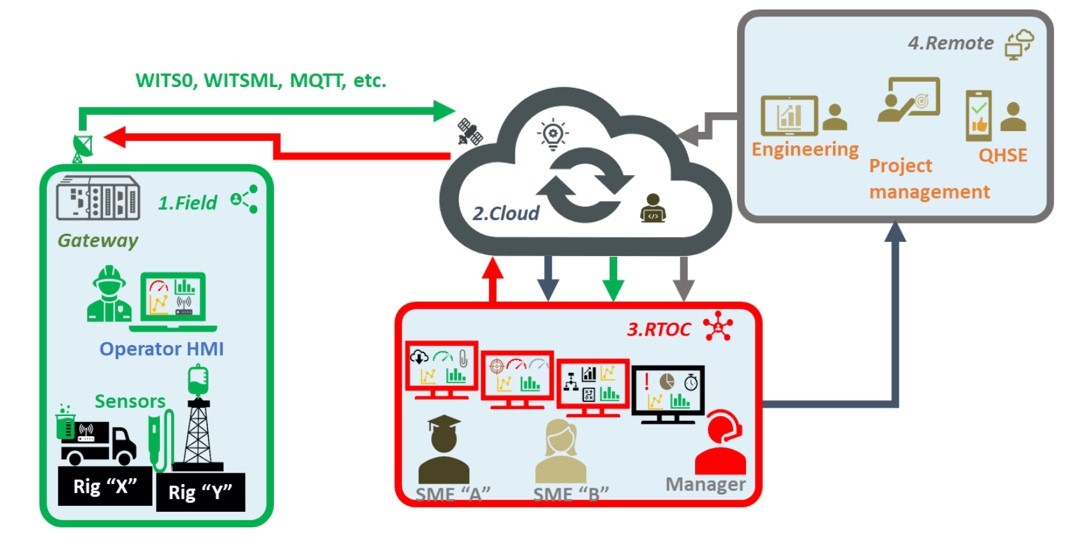

Technically speaking the digital ECO system consists of two major components the Cloud and Edge Compute Gateway having identical software, set to fit its location purpose (see Figure 3). The deployment scheme is flexible to a particular Client’s needs: starting from hybrid – cloud & private server on the remote end and gateway on the location – till cloud-only or even gateway only configurations. The Cloud portion of the ECO serves as a centralized data repository, remote access point, projects planning and engineering center, and post job analysis or retrospective analysis spot. The well-site ECO gateway serves as a real-time edge computing device of the ECO system. Gateway aggregates drilling contractor and services surface and downhole sensors measurements, analyze, and transmits data to the cloud. All project-approved well construction plans are automatically pushed from the cloud to the gateway before the activity commences. Once the well is spudded most of the actions are now performed on the Gateway side, where real-time data QA QC tools and the live dynamic digital twin of the drilled well reside and evolve along with the operations.

Figure 3. ECO system components, a scenario of the recommended deployment scheme.

Once operations are active ECO cloud gathers multi wells/rigs ECO cloud aggregated data, visualize it remotely, and performs correlation and benchmarking analysis.

ECO field software is working in the kiosk mode based on the Linux OS, allowing to minimize risks of malware, external intervention, dependency on the internet connection quality, and its bandwidth to transfer data while permitting robust autonomous operation 24/7. ECO structural components and automation business logic is agnostic to the equipment manufacturers. It does not require specific other than common instrumentation on the rig site. Each ECO system structural block could be used independently from other applications and in the particular user-specified/tuned mode, solving interoperability issues. ECO architecture allows to easily integrate it with the corporate, enterprise existing software platforms. All features and functions developed for specific applications are customizable per specific client needs and operational layouts during the commissioning phase and without axillary software development required.

ECO has been designed to become a cost-effective solution empowering drilling rig infrastructure while still using conventional data, rig, and downhole equipment. Its primary purpose is to reduce downhole hazards and QHSE risks, while continuously improving operational efficiency, hole quality, and field personnel competency.

The ECO system enables cloud and web technologies to provide safe continuous data access while optimizing IT infrastructure-related burden. Its automated analytics arsenal turns digital data into an actionable fit to purpose real-time, information targeted to increase resources and equipment utilization efficiency, automate processes, improving decision making time up to the levels of full automation.

Москва, 29 янв — ИА Neftegaz.RU. О цифровых решениях в бурении рассказывает Камиль Закиров — сооснователь цифровой платформы «ЭКО», выпускник Самарского государственного технического университета, Оксфордского колледжа энергетических исследований и Бизнес-школы университета INSEAD, в прошлом — вице-президент Weatherford International в России и странах СНГ и генеральный директор ГК Таргин.

Камиль Закиров

Соосновательпроекта ЭКО

Большинство изобретений в материальной части нашей индустрии были сделаны годы и десятилетия назад. Во всех трех направлениях на сегодняшний день решения близки к идеальным: индустрия обладает огромным опытом и обширными данными, на которых строятся все следующие решения; оборудование и технологичное, и надежное; уровень оптимизации бизнес-процессов на максимально высоком уровне. Подавляющее большинство последних изобретений и нововведений находятся на уровне «улучшайзинга», каждое из которых улучшает общую экономику на доли процентов, и кажется, что больших революций не предвидится.

Где найти возможность получить действительно значимые изменения, способные одновременно повысить качество и безопасность буровых работ, увеличить скорость строительства скважин и уменьшить общие затраты на строительство скважин на 20 % и на 30 %?

Большой прорыв следующего уровня нам даст цифра. Не просто абстрактная цифра, а я бы сказал, умная и комплексная цифра, способная моделировать, анализировать, предсказывать и управлять. Мы видим, что с развитием технологий наиболее слабым звеном агрегатно-механических систем становится человек, этими системами управляющий. Человек не способен производить массированные и бесперебойные вычисления, он может забывать или ошибаться, человек устает. Ну и просто не во всех средах человек может находиться и работать.